GLOBAL AVIATION SOLUTION LLC service provides comprehensive avionics installations,

repairs, modifications, and is an authorized dealer for all major avionics manufacturers.

We are a leading supplier to the largest OEM manufacturers in the USA.

We provide them special offers, fixed prices and superior customer service.

Our goal is to forge partnerships, create value, deliver quality,

and build trust by understanding the needs of our clients.

Our goal is to forge partnerships, create value, deliver quality,

and build trust by understanding the needs of our clients.

Our unique manufacturing flexibility and expertise gives us nearly

unlimited capabilities in customization.

Our unique manufacturing flexibility and expertise gives us nearly

unlimited capabilities in customization.

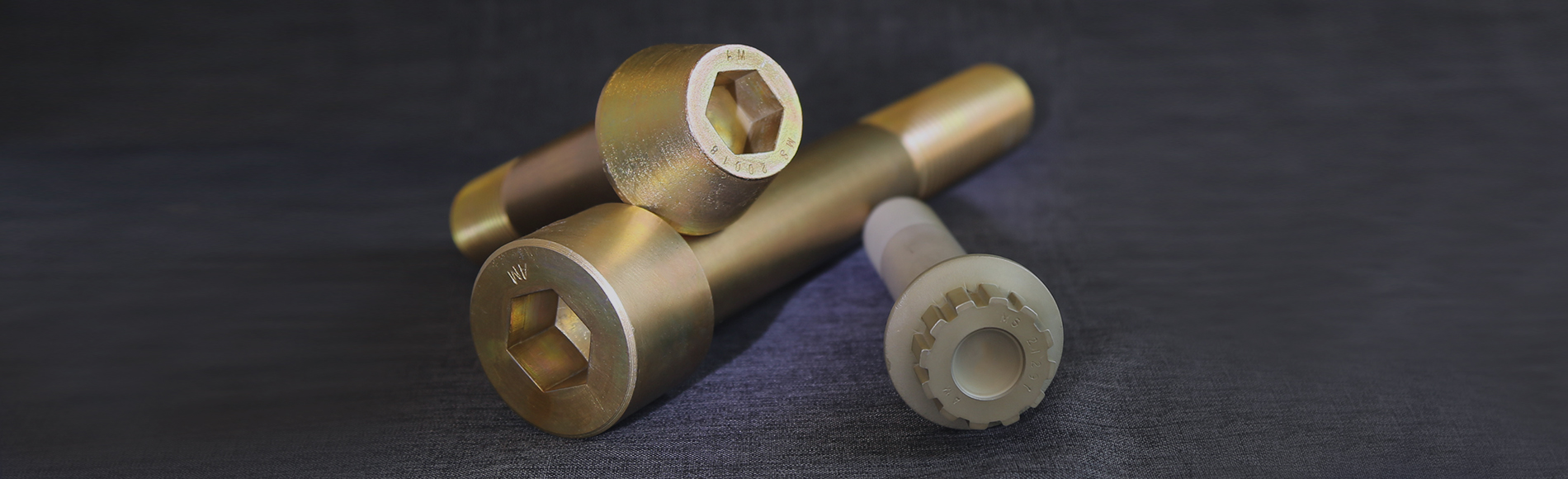

We can offer high quality fasteners for both large and small

original equipment manufacturers .

We can offer high quality fasteners for both large and small

original equipment manufacturers .

We offer same-day shipment on stock items and very short lead-times

of one to four weeks on high strength and close tolerance fasteners.

We offer same-day shipment on stock items and very short lead-times

of one to four weeks on high strength and close tolerance fasteners.

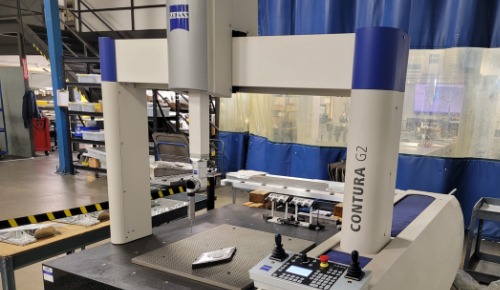

Quality is Global Aviation Solutions’ top priority. We pride

ourselves on delivering high quality fasteners.

Quality is Global Aviation Solutions’ top priority. We pride

ourselves on delivering high quality fasteners.

Global Aviation Solutions’ success is built on a deep knowledge and

understanding of the stringent requirements of the aerospace

industry’s needs.

Global Aviation Solutions’ success is built on a deep knowledge and

understanding of the stringent requirements of the aerospace

industry’s needs.